Viscotec

PET sheet extrusion

Viscotec is the only machine able to produce food-grade PET film using 100% post-consumer recycled PET bottle flakes. With up to 2.0 mm in film thickness, it is easily unmatched in the industry.

—

Featured

our best-selling machines

Explore how you can save with lower material costs, lower specific electric consumption, and smooth installation with our popular Viscotec machines.

—

viscoSHEET

viscosheet machine

Up to 100% recycled materials, input materials include PCR bottles flakes, post-industrial regrind, and pellets.

PET bottle flakes

film thickness

deCON 20

decontamination machine

Decontamination of PCR flakes according to EFSA and FDA. Input materials include PCR pellets, PCR bottle flakes, in-house skeleton waste.

Max. output

rest humidity

deCON 50

Decontamination machine

Decontamination dryer for production of dry, food grade flakes or skeleton waste directly in front of production extruder.

max. output

rest humidity

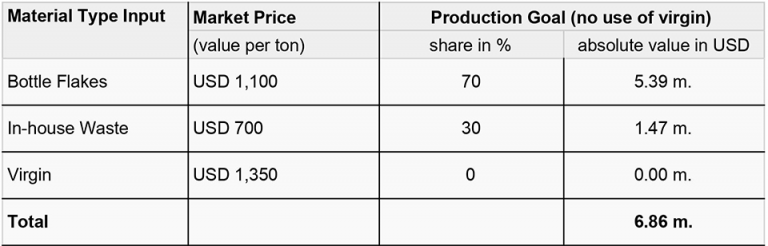

Material Savings

Market prices show significant material cost savings from PET flakes compared with virgin material, up to 70% lower price for post-consumer recycled PET bottle flakes.

food-grade

Decontamination machines are FDA and EFSA approved for the highest international standards. Design ensures constant treatment time of material in the reactor.

Energy Savings

Energy-efficient decontamination machines ensure low specific electrical consumption (kWh/kg).

vacuum treatment

Due to the reduction of the boiling temperature, all contaminants evaporate when reaching the PET surface. Dynamic vacuum treatment results in a shorter residence times at lower temperatures.

Easy installation

Incredibly smooth start up operations with new and existing machines, featuring a “plug-and-play” installation.

after sales service

PT. Triputra Innovasijaya provides 24/7 technical service and automation consultations for maximising production efficiency.

Material Savings

Use as much post-consumer recycled flakes as possible, use edge trims for sheet production and skeleton waste for thermoforming.

(per year per machine)

food-grade quality

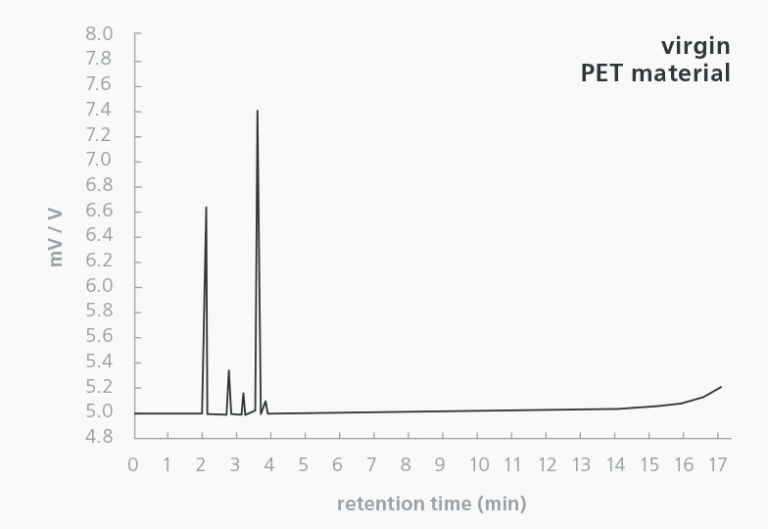

Gas chromatographies are used for testing the purity of PET. Constant long-term screenings at customer sites worldwide confirm the excellent cleaning efficiency of the deCON.

Contact Us

—

Phone

Office

Social

Looking for a free consultation or price quotation? Get in touch with us.