Bekum

Extrusion Blow Moulding

Explore our high output and low cycle time Bekum machines below.

—

Featured

our best-selling machines

Find out how to save money with lower production costs, material savings, specific electrical consumption and more.

—

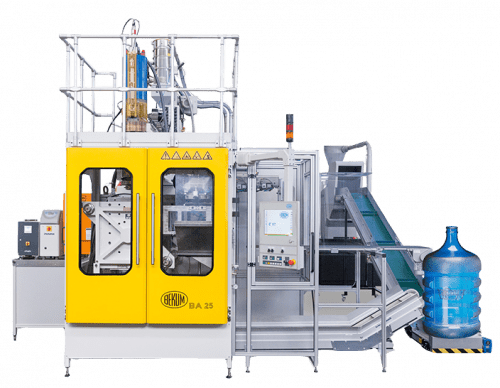

Bekum BA 25

Water Gallon machine

Single-station machine production of 5-gallon water bottles made with Polycarbonate (PC) or PET.

Cycle time

output rate

Bekum Eblow 607D

Milk bottle machine

Food & beverage packaging machines use sterile blowing for sensitive filling goods like milk and juices. HDPE production of 100ml milk bottles.

Cycle time

output rate

Bekum BA 34.2

Jerrycan machine

Single-station single-cavity production of 20L jerry can. Made of 3-layer HDPE and recycled materials.

Cycle time

output rate

Bekum BM 704D

Double station machine

Double-station machine for production of jerrycans and bottles.

2 x 5-fold production of 1L motor oil bottles.

Cycle time

output rate

2 x 2-fold production of 5L jerrycans.

Cycle time

output rate

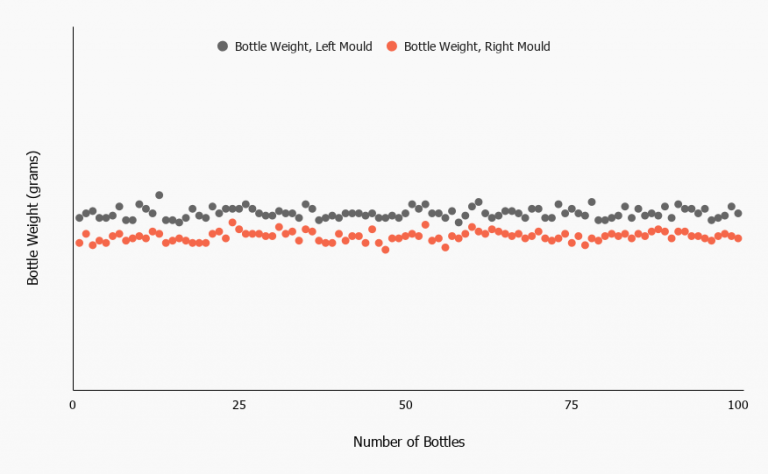

Material Savings

Reduce raw material costs by mixing virgin plastic with recycled materials or fillers using Bekum's 3-layer technology. Spiral mandrel extrusion heads allow thin-walled packaging with a low weight deviation of under ± 1%.

Energy Savings

Energy-efficient machines ensures low specific electrical consumption (kWh/kg). Bekum’s state-of-the-art extruder lowers production costs by reducing energy consumption by up to 20%.

High Output

Smaller bottle volumes can be manufactured reliably and in very high volumes of over 23,000 pcs./hour using the Tandem Blow technology developed by Bekum.

Low cycle time

A 20 L Jerry can weighing 1000g is produced in 18s cycle time on a single station, single cavity machine. A 1 L lubricant bottle weighing 65g is produced in 12.5s cycle time on a multicavity 6+6 machine.

food-grade

Bekum’s co-extrusion technology allows bottles blown with up to 7 layers for increasing shelf life in sterile conditions.

after sales service

PT. Triputra Innovasijaya provides 24/7 technical service and automation consultations for maximising production efficiency.

Material savings

Weight deviation is used for calculating raw material savings per bottle. Constant long-term testing at customer sites confirm the low weight deviation of under ± 1% in Bekum machines.

(per year per machine)

Contact Us

—

Phone

Office

Social

Looking for a free consultation or price quotation? Get in touch with us.